Case report: #19NY038

Issued by: New York State Fatality Assessment and Control Evaluation Program

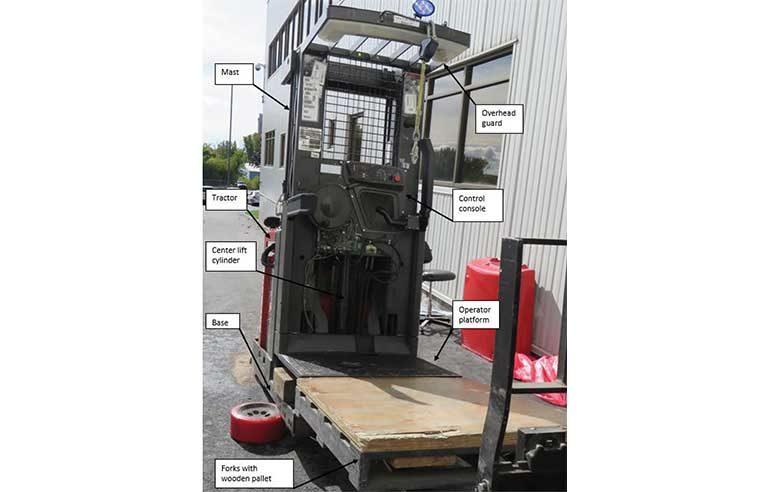

Date of report: Aug. 10, 2022A 58-year-old mechanic service technician for an equipment service and sales company was servicing an order picker with a co-worker. The picker’s carriage, which weighs nearly 1,200 pounds, consists of an operator platform, a control console and lift forks. The carriage’s movement is actuated by a center lift hydraulic cylinder and a pair of side lift cylinders, along with a set of chains and pulleys. The center lift cylinder, which has a hydraulic pressure of more than 2,000 pounds per square inch, had a minor leak, and the technician and the co-worker were onsite to replace some parts. To access the cylinder, they removed the control console cover and raised the carriage about 7 feet. According to the co-worker, the technician was holding a pair of snap ring pliers while standing directly underneath the carriage – which was neither chained nor blocked to prevent it from falling. The technician used pliers to remove the outer snap ring from the cylinder, apparently to verify the part number. The function of the outer snap ring is to hold and secure the oil seal of the cylinder at the rod end. While the technician was telling his co-worker he “just wanted to look” at the ring, the carriage fell quickly, crushing him underneath. Hydraulic fluid sprayed onto the entire dock area. The co-worker tried to use a jack to lift the carriage but was unsuccessful. Emergency responders arrived within minutes. The technician was pronounced dead at the scene.

Issued by: New York State Fatality Assessment and Control Evaluation Program

Date of report: Aug. 10, 2022A 58-year-old mechanic service technician for an equipment service and sales company was servicing an order picker with a co-worker. The picker’s carriage, which weighs nearly 1,200 pounds, consists of an operator platform, a control console and lift forks. The carriage’s movement is actuated by a center lift hydraulic cylinder and a pair of side lift cylinders, along with a set of chains and pulleys. The center lift cylinder, which has a hydraulic pressure of more than 2,000 pounds per square inch, had a minor leak, and the technician and the co-worker were onsite to replace some parts. To access the cylinder, they removed the control console cover and raised the carriage about 7 feet. According to the co-worker, the technician was holding a pair of snap ring pliers while standing directly underneath the carriage – which was neither chained nor blocked to prevent it from falling. The technician used pliers to remove the outer snap ring from the cylinder, apparently to verify the part number. The function of the outer snap ring is to hold and secure the oil seal of the cylinder at the rod end. While the technician was telling his co-worker he “just wanted to look” at the ring, the carriage fell quickly, crushing him underneath. Hydraulic fluid sprayed onto the entire dock area. The co-worker tried to use a jack to lift the carriage but was unsuccessful. Emergency responders arrived within minutes. The technician was pronounced dead at the scene.

To prevent similar incidents, employers should:

- Develop specific lockout/tagout procedures for service technicians to follow.

- Ensure service technicians follow manufacturers’ safety requirements and standard safety procedures.

- Conduct a job hazard analysis to identify hazards and risk factors associated with lift truck maintenance and repair.

- Ensure all service technicians receive proper and adequate training on lockout/tagout procedures.

- Develop checklists for high-risk maintenance tasks and require technicians to check each step and sign the checklist.

- Conduct periodic inspections at client sites to ensure the sites are free of hazards and workers are following safety protocols.

McCraren Compliance offers many opportunities in safety training to help circumvent accidents. Please take a moment to visit our calendar of classes to see what we can do to help your safety measures from training to consulting.